About us

WELCOME TO

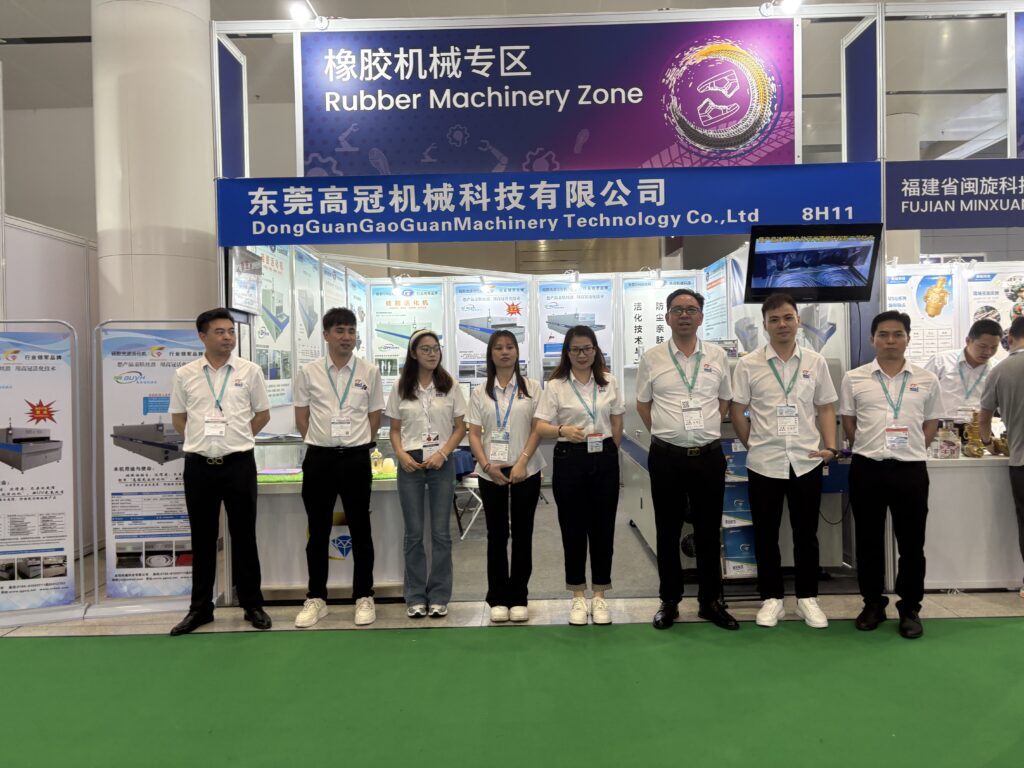

GAOGUAN MACHINERY TECHNOLOGY

Company Profile

1.Who are we?

Fast Facts

Milestone: Over 15 years of dedicated expertise in silicone activation technology

Hub of Innovation: Based in Dongguan, China—the epicenter of advanced industrial machinery manufacturing

Cutting-edge Tech: Powered by proprietary 4-in-1 GH activation system, integrated with German-engineered GUV lamps

Precision: Achieve molecular-level treatment accuracy, ensuring surface energy consistency within ±3% variance

Scale: Capable of upgrading production efficiency by 200%+ for customers, with 1000+ global clients served

Core Products

Innovative Solutions, Tailored for Silicone Excellence

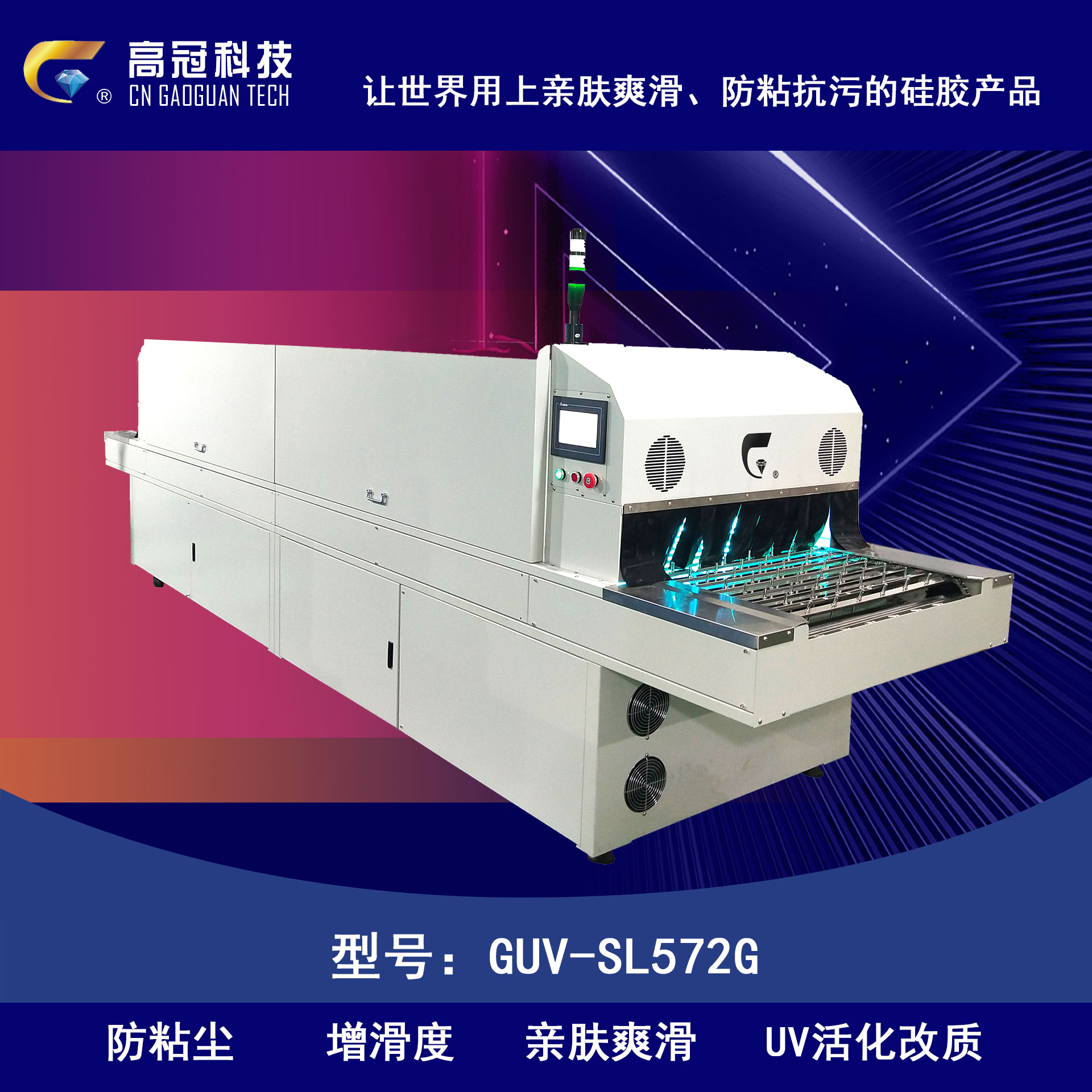

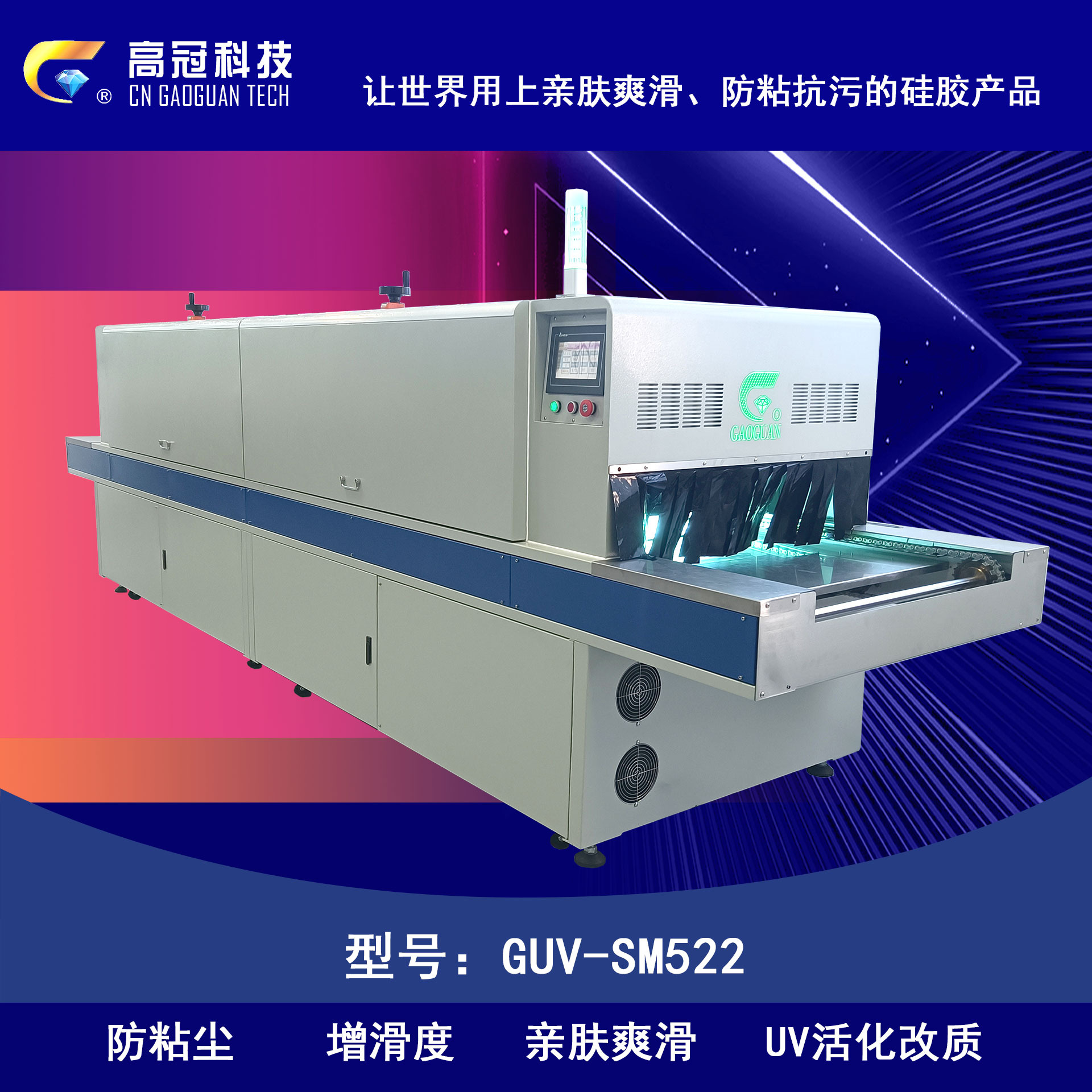

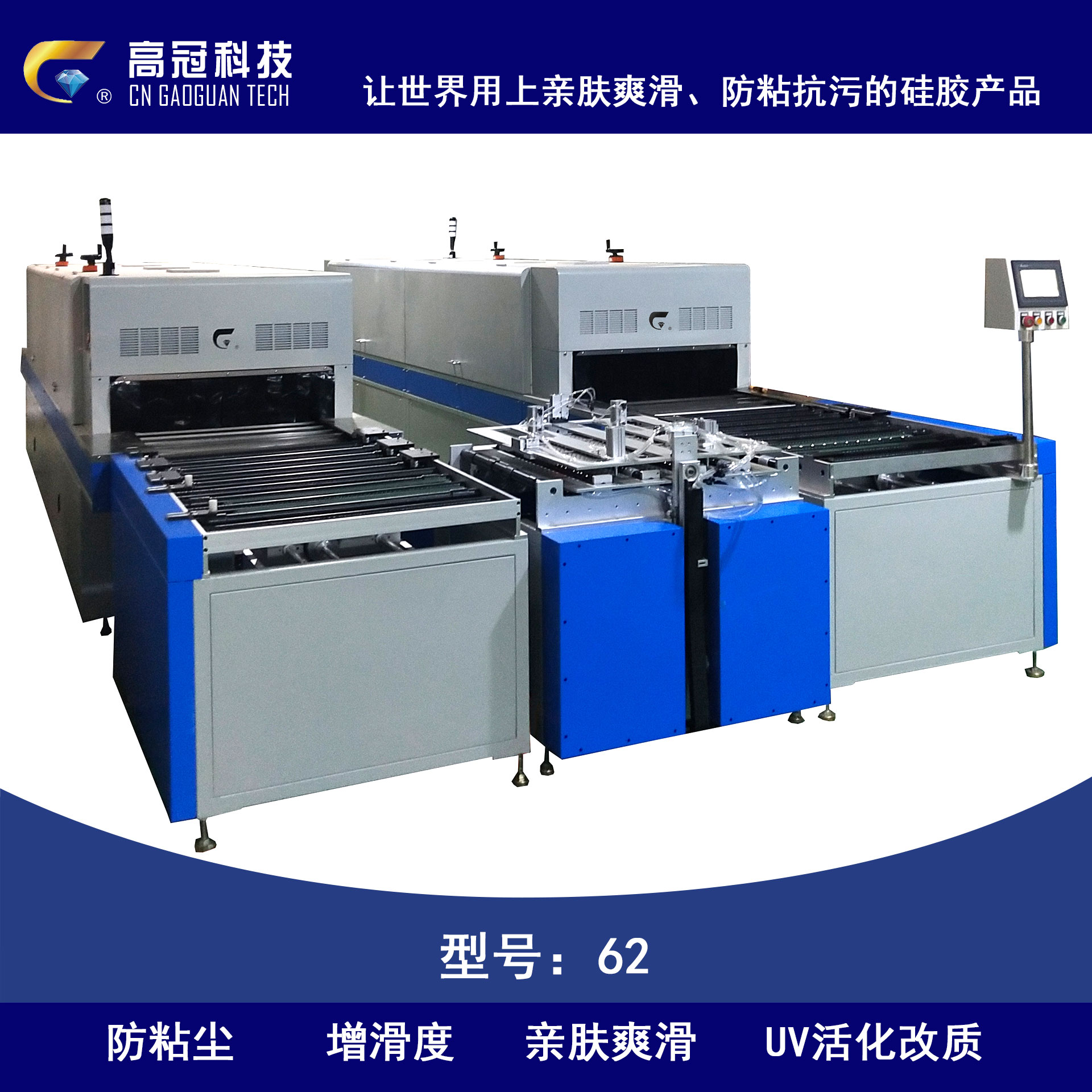

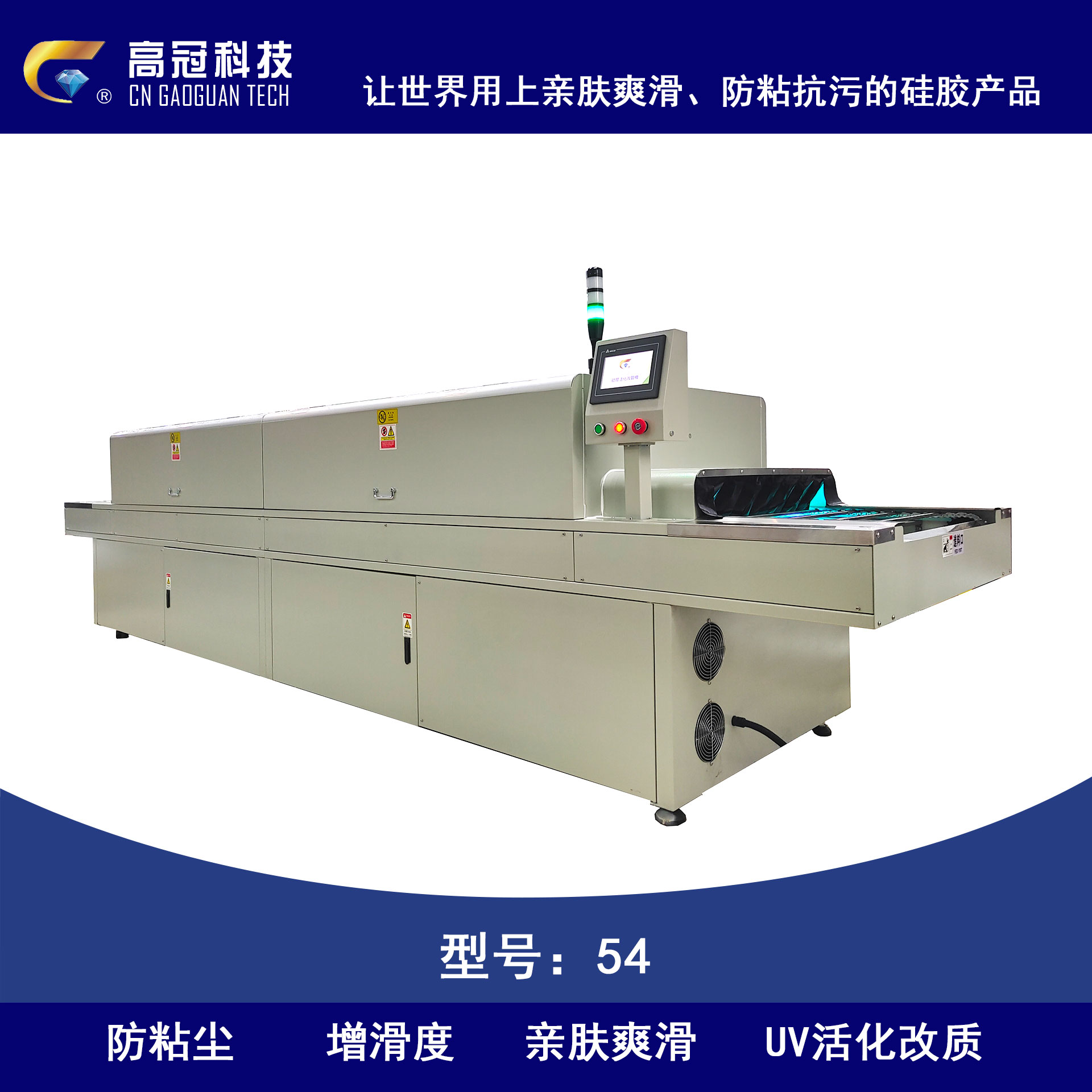

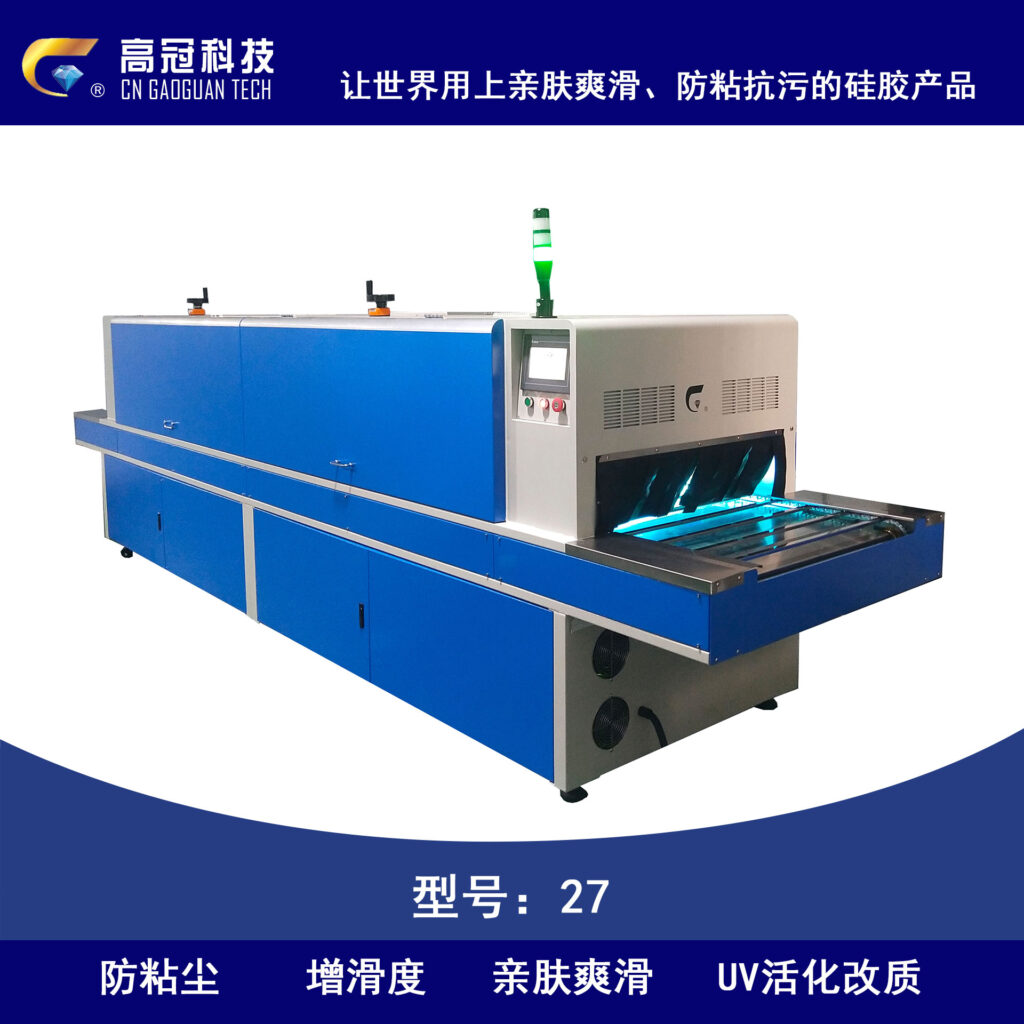

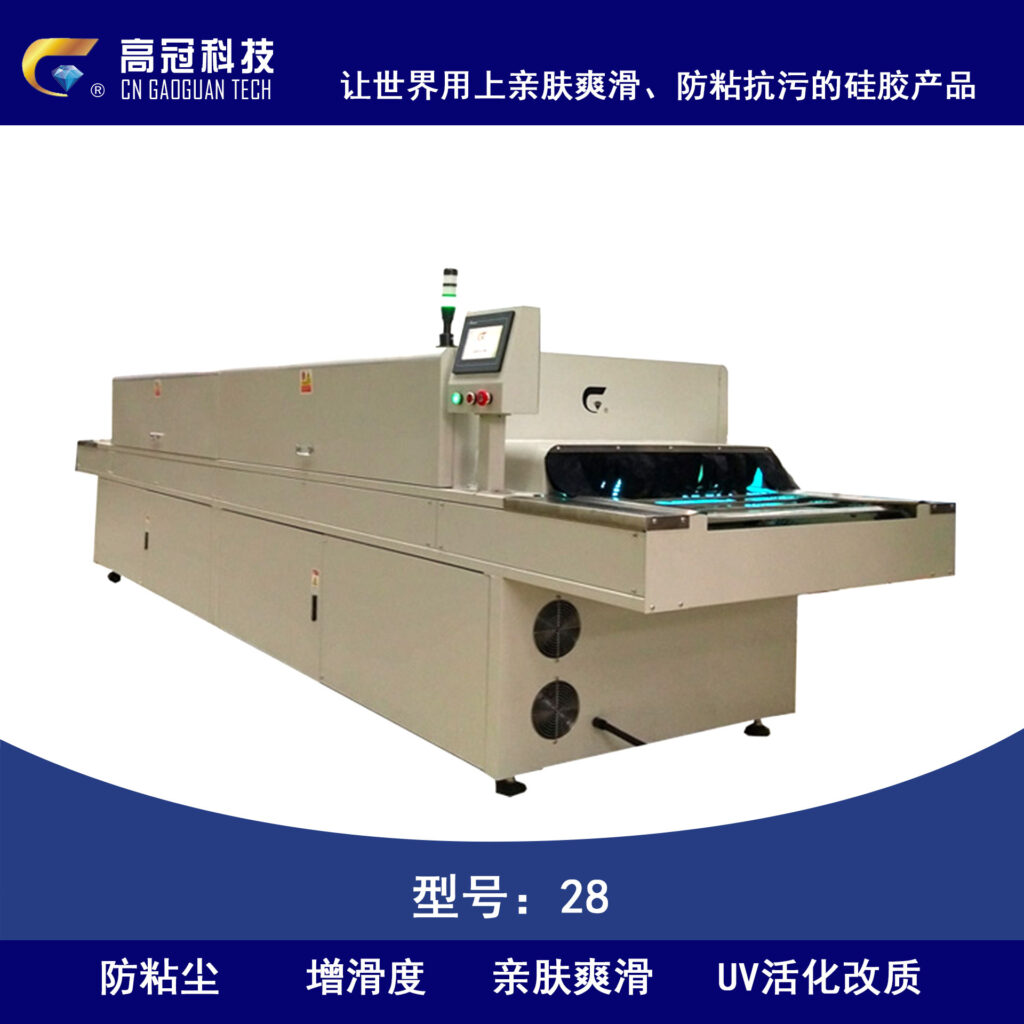

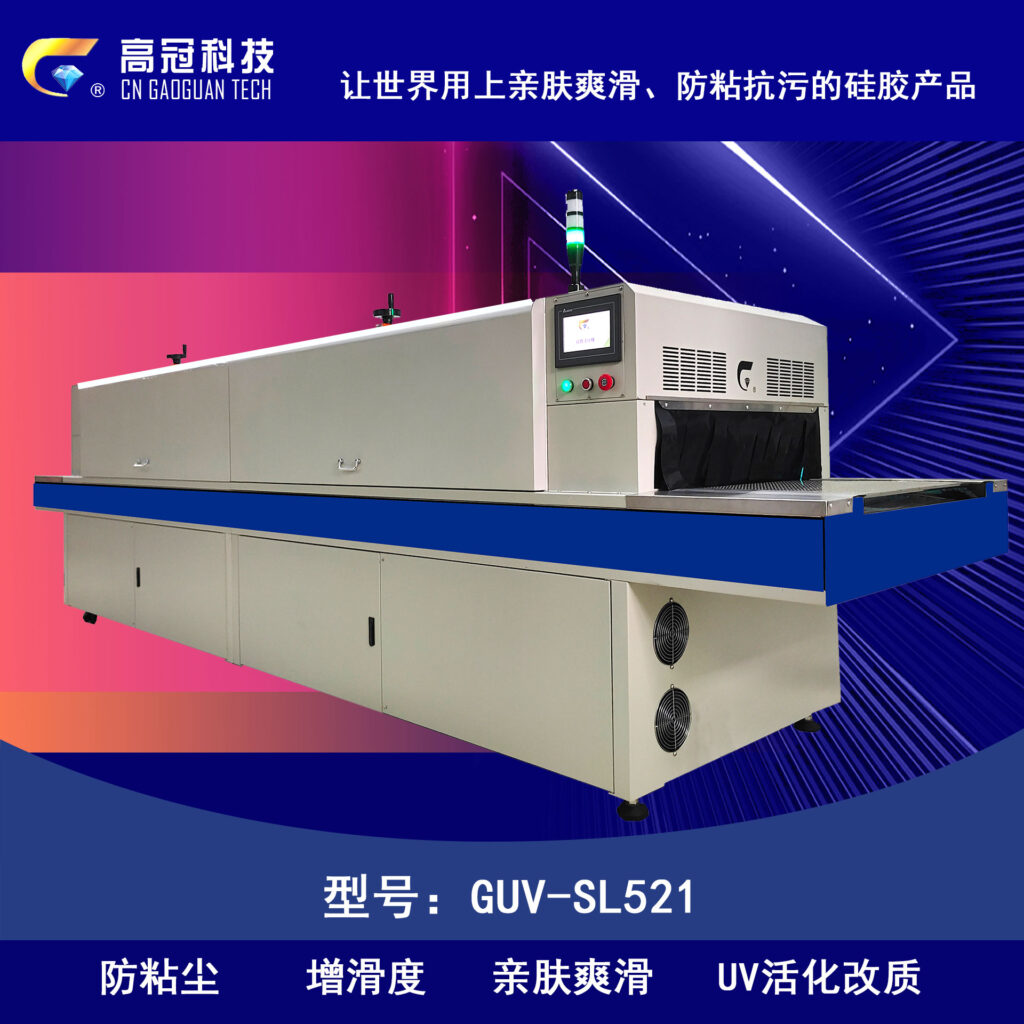

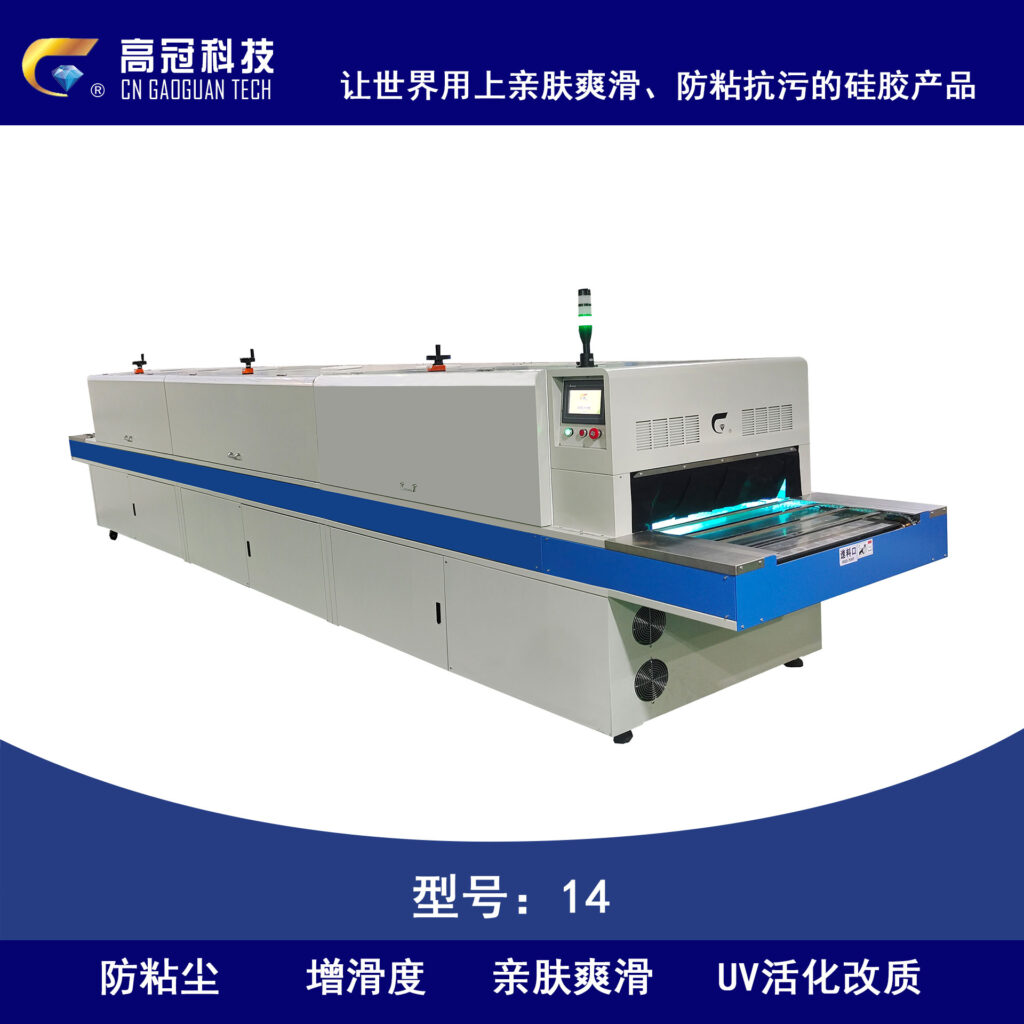

1. Intelligent Silicone Activation Machine Series

- Achieves surface energy consistency within ±3% and boosts hydrophilic group density by 40%, ensuring ≥90% dust resistance and skin-friendly smoothness.

- Modular architecture supports single/double-side activation, with tunnel-type models processing up to 2,000 pieces/hour for flat silicone components (e.g., electronic seals, medical tubing).

- Compatible with all silicone grades—from food-grade to high-temperature variants—meeting FDA/REACH standards for diverse industry applications.

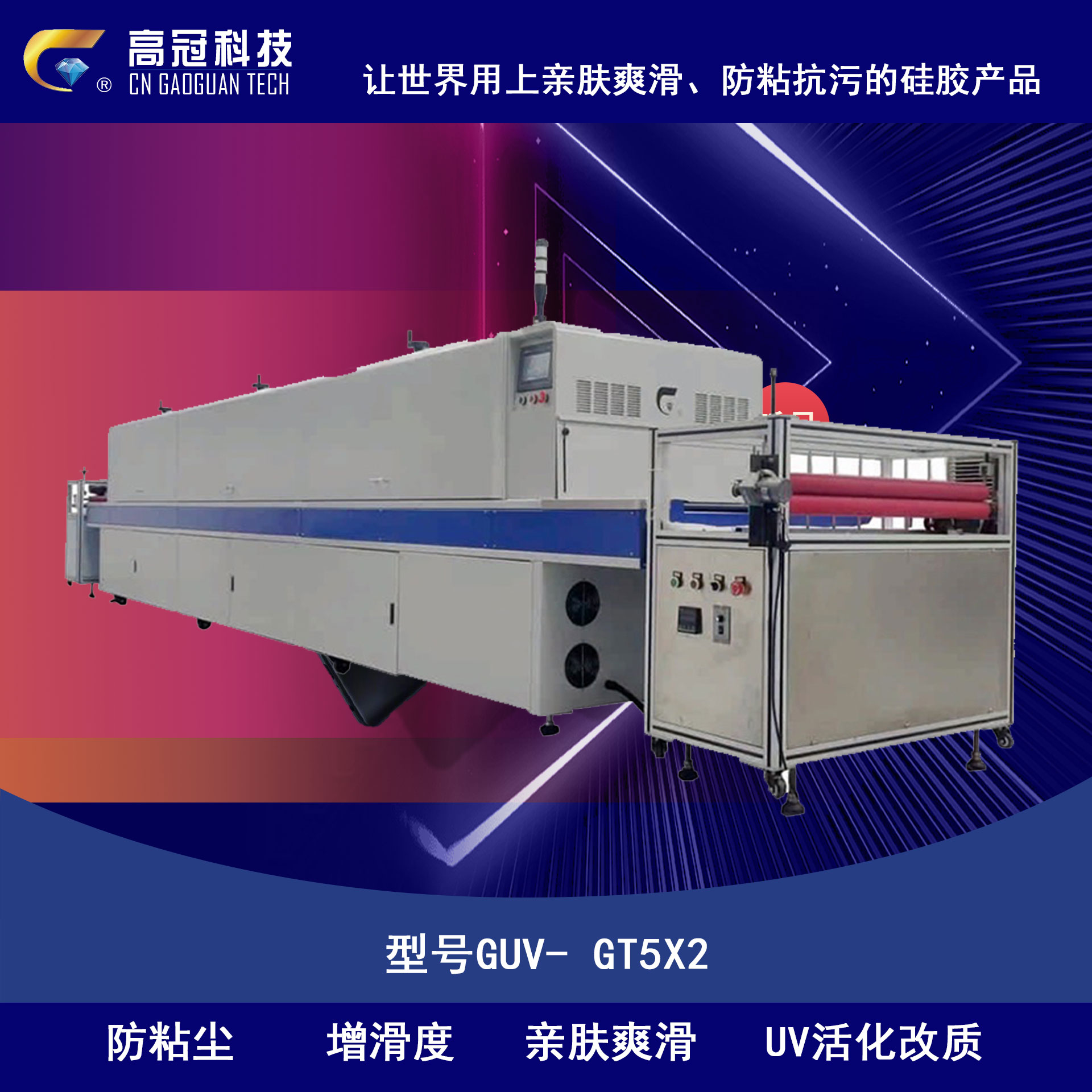

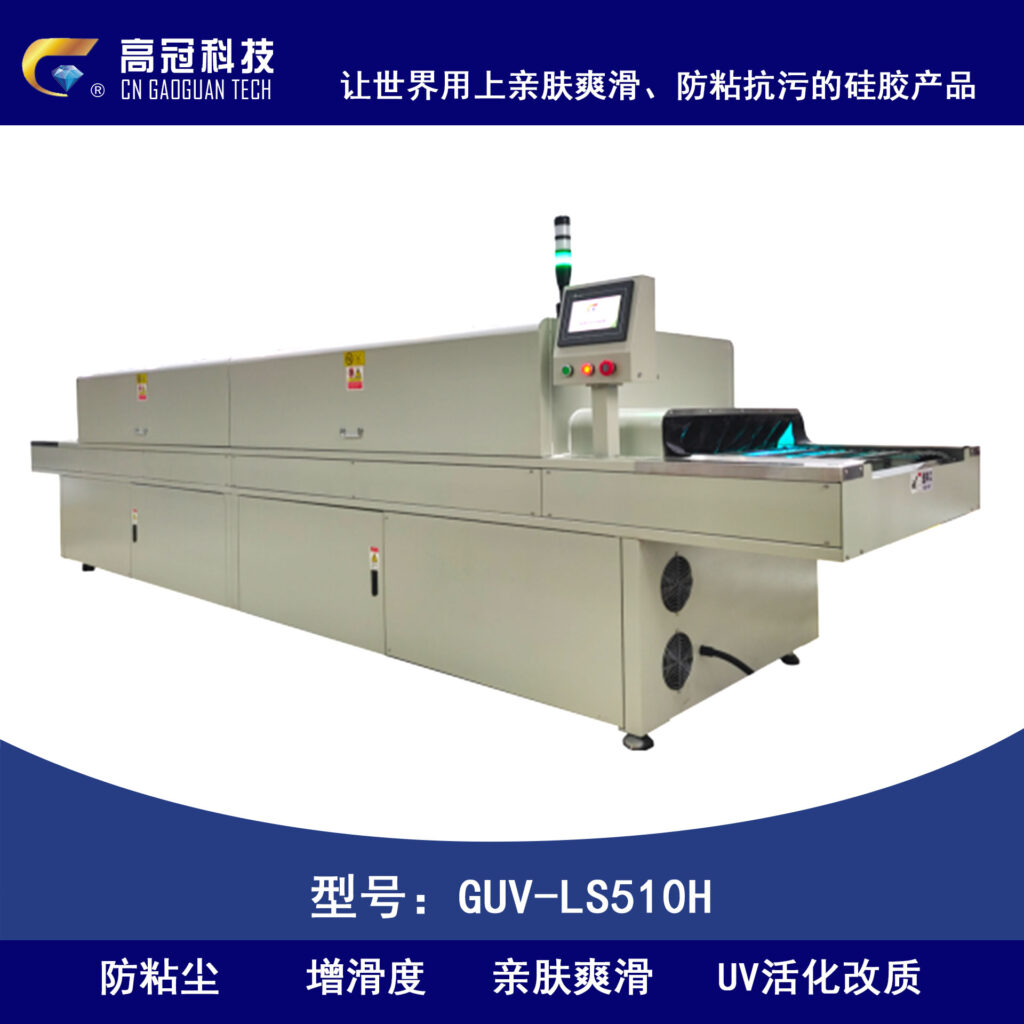

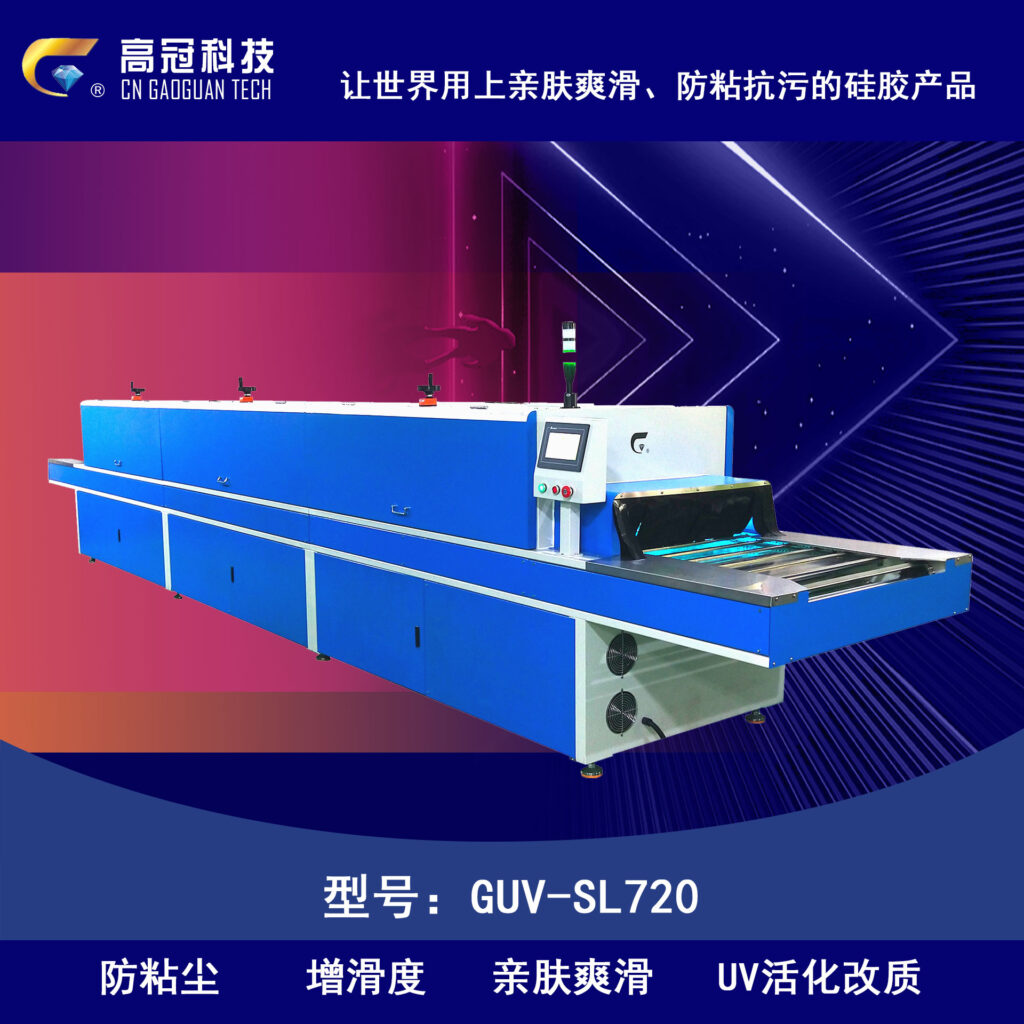

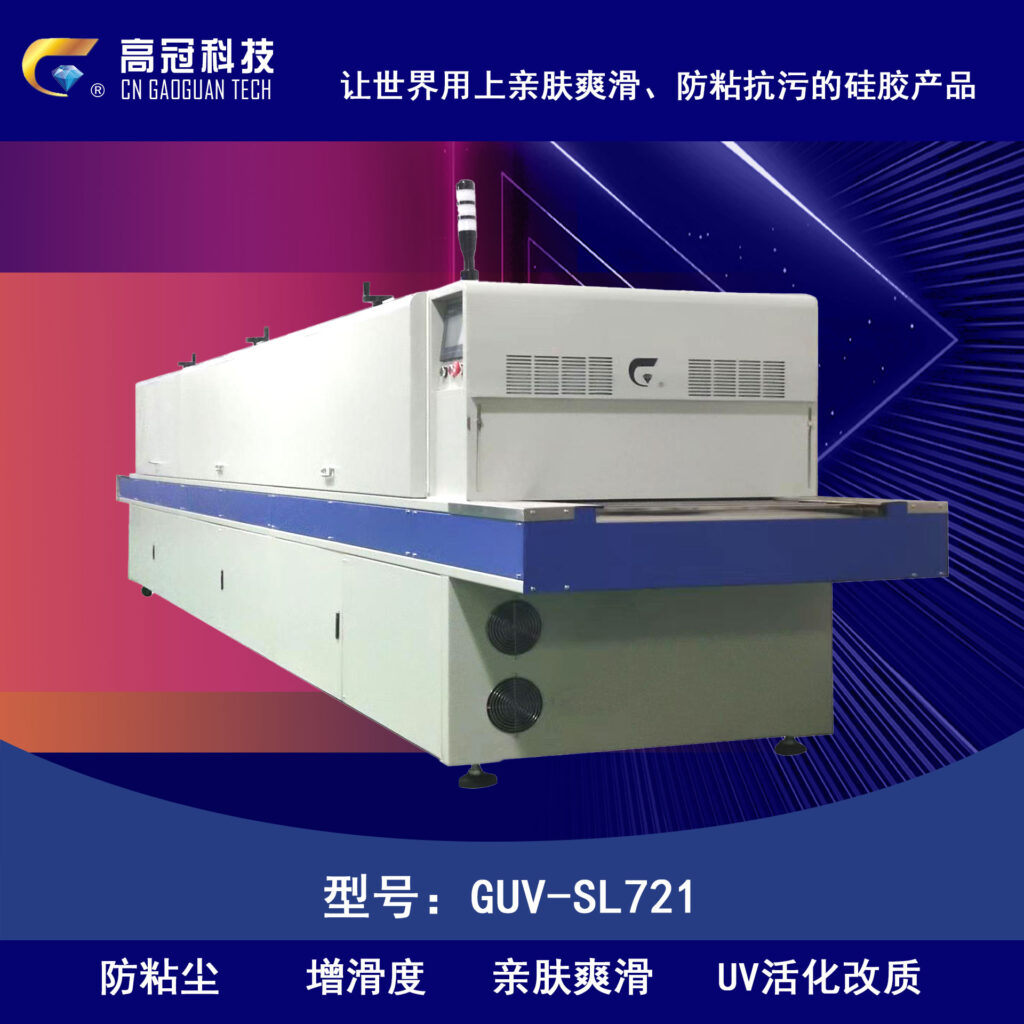

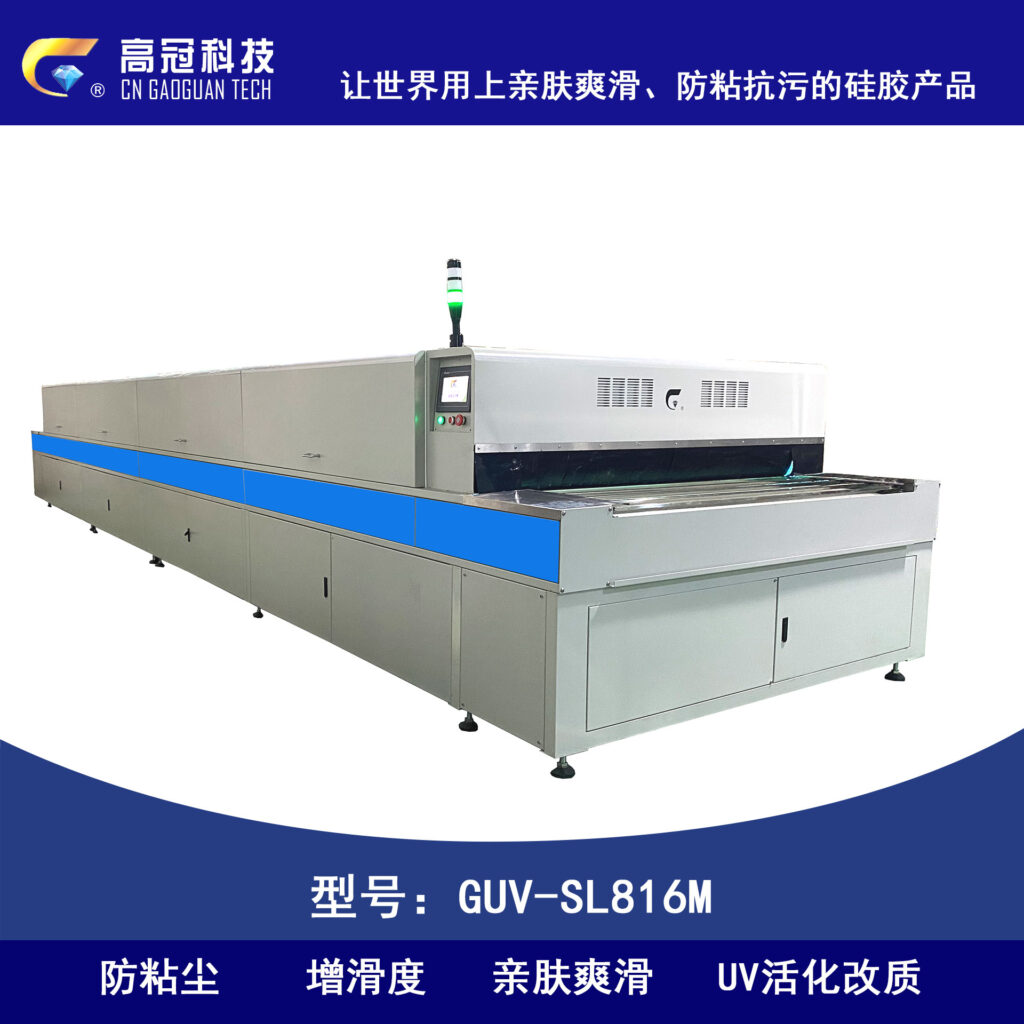

2. High-Energy GUV-IRH Activation System

- Smart Control: Siemens PLC-integrated touchscreen enables real-time monitoring of activation intensity, temperature (78-88℃ precision control), and energy consumption (6.5-8kWh/h, 45% lower than traditional methods).

- Scalable Production: Ideal for mass manufacturing, with hanging-type models supporting continuous 24/7 operation for large components like automotive gaskets and industrial seals.

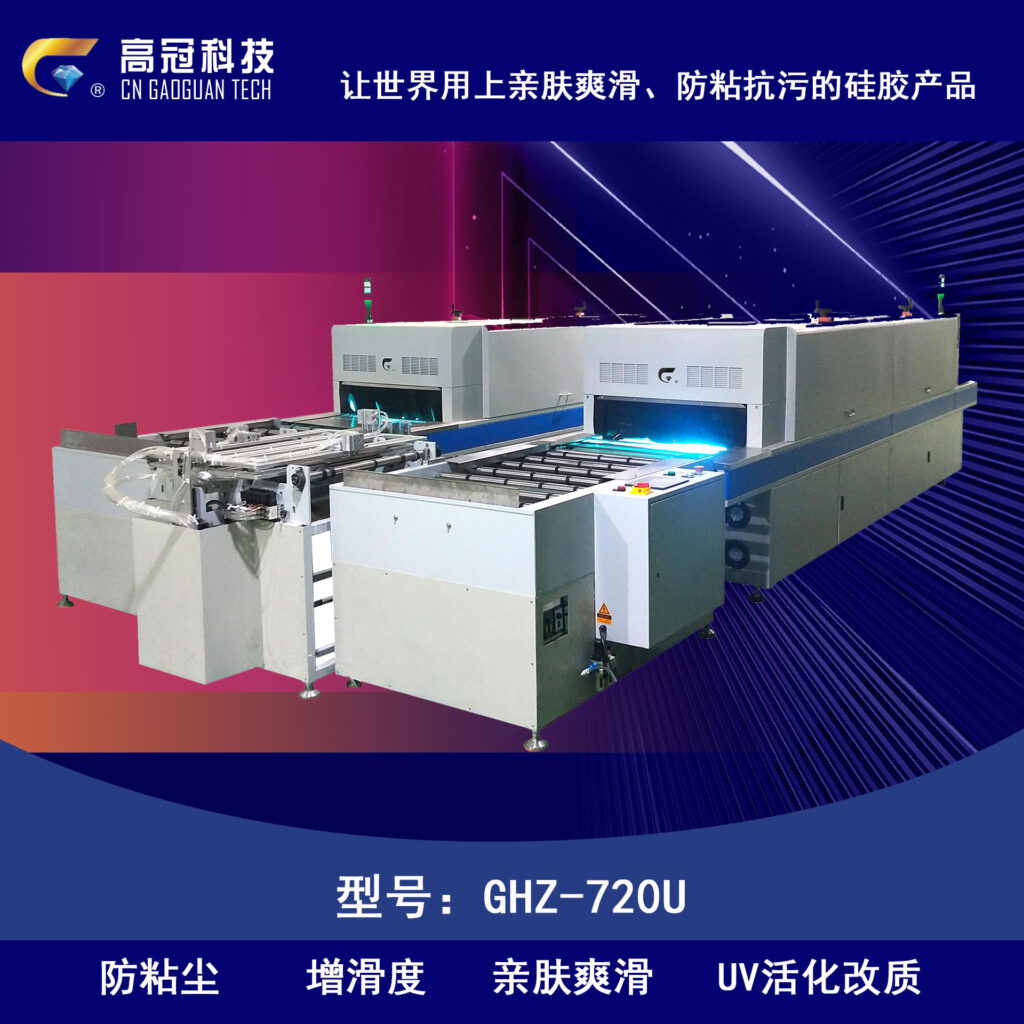

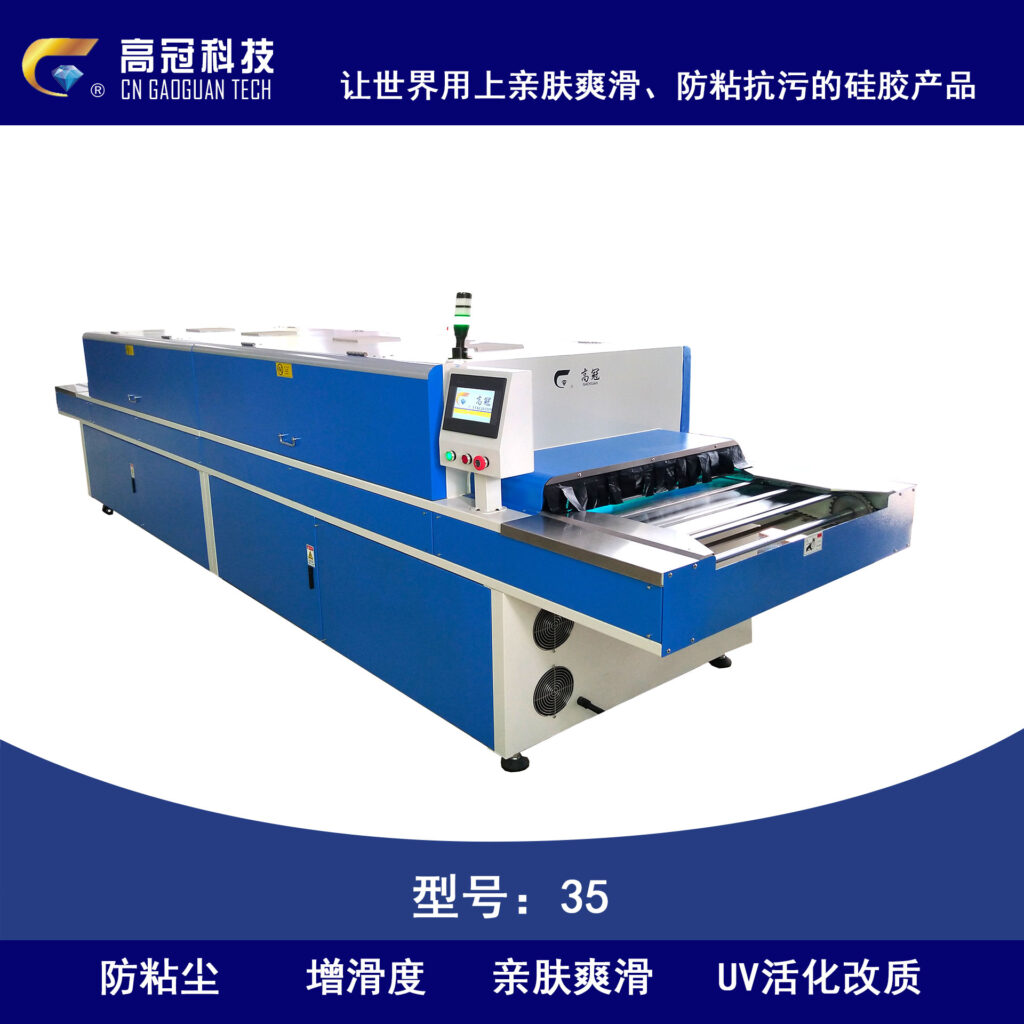

3. Modular Eco-Activation Cell Series

- Customizable Configurations:

- Power modules: 380V/220V adaptive for global markets, with export-specific voltage solutions.

- Automation upgrades: Robotic arm integration for unmanned production lines, supporting 360° rotation for complex geometries.

- Post-treatment options: Integrated dust removal and surface testing modules for complete quality assurance.

- Application Scenarios: Perfect for small-to-medium batches of high-precision parts (e.g., baby products, wearable device components), with quick mold changeover reducing setup times by 50%.

Intelligent Silicone Activation Machine Series

High-Energy GUV-IRH Activation System

Modular Eco-Activation Cell Series

Other products

2.What do we do?

3.Why choose us?

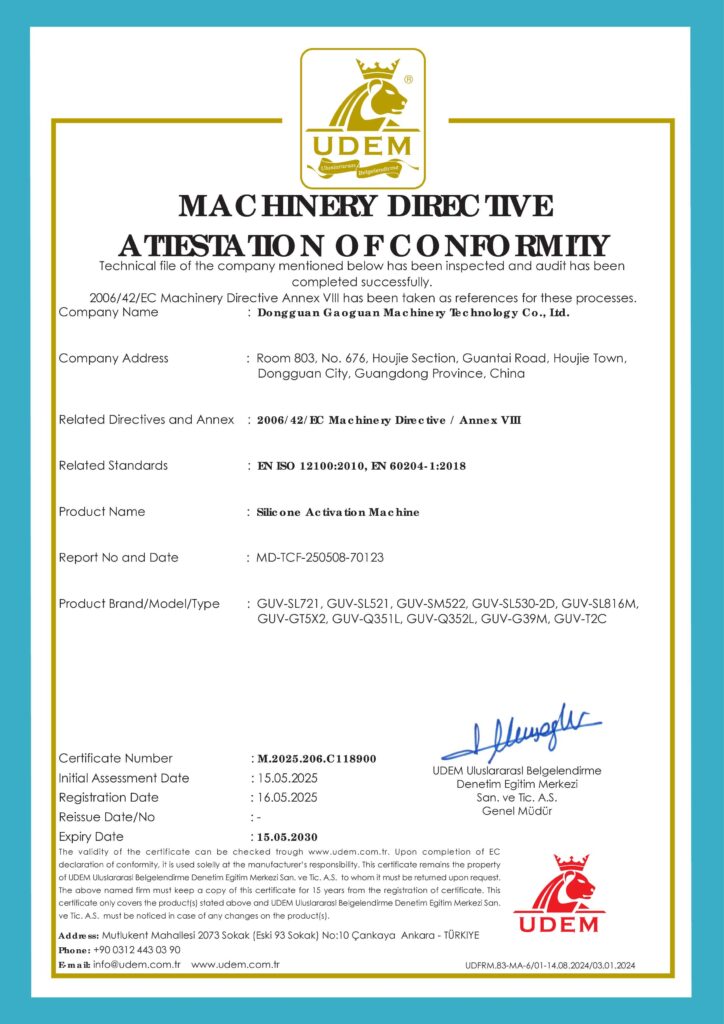

Guided by the philosophy of “High Precision, Global Excellence”, we pioneer silicone surface innovation with a mission to lead the industry toward eco-friendly manufacturing. Our 4-in-1 GH Activation Technology—backed by 39 national patents and ISO certifications—replaces 39 years of oil-based practices, delivering molecular-level precision that achieves 90% dust resistance and medical-grade skin smoothness.

Why Partner With Us?

- Technological Leadership:German-engineered GUV systems and 8500MJ+ activation energy, cutting energy use by 45% while eliminating 90% of VOC emissions.

- Uncompromising Quality:Full-process QC from component sourcing to final testing, ensuring a 98.5% first-pass yield for clients like Huawei and Procter & Gamble.

- Sino-German Expertise:A team of engineers from China and Germany who’ve spent 15+ years perfecting oil-free activation for electronics, medical devices, and automotive applications.

- Global Service Ecosystem:7×24 after-sales support, 1-hour response times, and modular upgrades to future-proof your production.

Philosophies and Values

corporate ethos is anchored in the principles of “Trust, Team, Efficiency, Service, Innovation”—guiding lights that shape our culture and define operational excellence. Trust forms the foundation of every partnership, built through unwavering integrity and transparency. Teamwork fuses diverse expertise into a cohesive force, driving collective problem-solving. Efficiency is a strategic imperative, realized through lean processes and technological innovation.

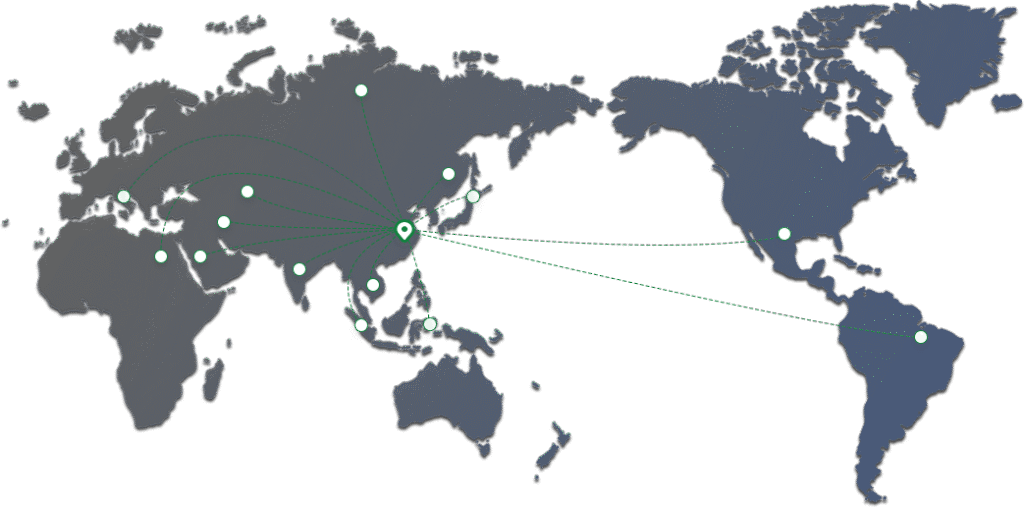

Sales network

The products are mainly exported to the United States, Japan, Australia, Europe, the Middle East and other countries and regions

It is popular in countries such as Europe, America and Southeast Asia all over the world